Home Blog Product Info Everything You Need to Know About Steel Road Plates

Steel Road Plates play a crucial role in construction and infrastructure projects, and rightfully so. With their incredible durability and robustness, along with their ability to be used in an extremely wide range of construction applications, it’s likely that Steel Road Plates will find a place on your construction site.

In this comprehensive guide, you will learn all you need to know about our Steel Road Plates, including what they are, what applications they can be used for, their features and benefits, and whether you should hire or buy them for your projects.

WHAT ARE STEEL ROAD PLATES?

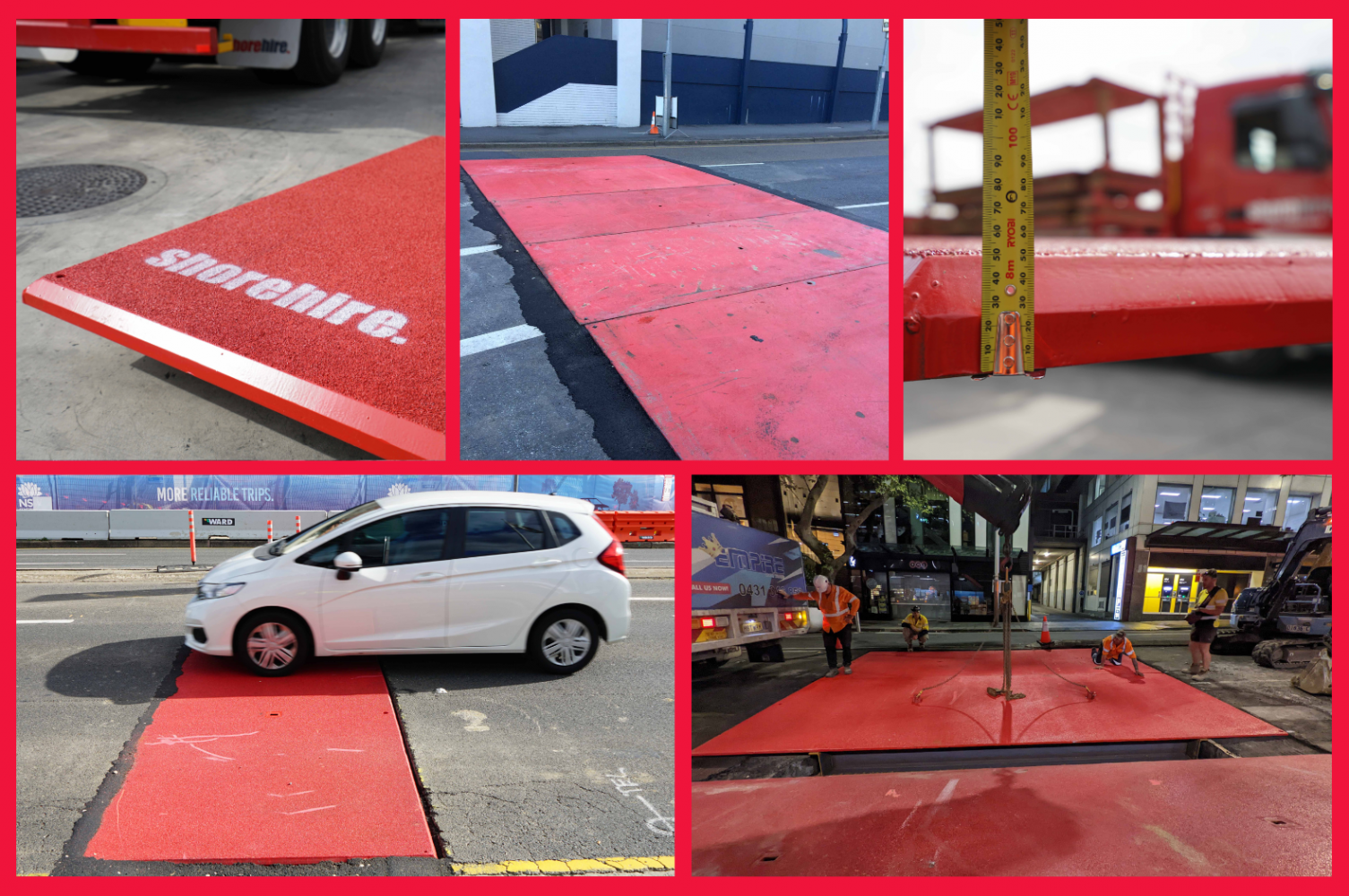

Steel Road Plates are heavy-duty steel coverings that provide safe, temporary access over excavations and access for temporary works for vehicles and pedestrians.

Shore Hire stocks one of the largest ranges of Steel Road Plate sizes in Australia, with plates ranging in size from 1200mm x 1200mm up to 6000mm x 2400mm, and available in thicknesses of 25mm, 32mm, and 50mm.

The width and thickness of a Steel Road Plate used on a project depend on the width of an excavation or the area that needs to be covered and the type of traffic (pedestrians, vehicles, etc.) using or passing over the plate.

WHAT ARE STEEL ROAD PLATES USED FOR?

Steel Road Plates play a key role in our business and can be used in essentially any application that requires them. However, the most common uses we see are:

- Driveway access: Steel Road Plates can be placed over the beginning of a driveway, along curbs, or over gutters to create a safe and stable surface for vehicles and pedestrians to travel across.

- Road crossings and Temporary Roads: Steel Road Plates are often placed on roads when excavations, maintenance work, and other types of construction happen. They can help to minimise disruptions to traffic or even create a temporary section of road that vehicles can drive over

- Excavation protection: In one of their most common uses, Steel Road Plates can be installed over open excavations to help prevent accidents, ensure worker or pedestrian safety, and can even protect trenches, and the work that’s being done in them, from heavy rain, snow, or wind. Using Steel Road Plates as temporary ‘lids’ for excavations usually requires engineering sign-off. Plates may often need stiffener beams to be welded on to reduce deflection (bending), especially on major roads.

- Pedestrian access: Steel Road Plates can be placed on or over a number of hazards on construction sites, such as excavations, trenches, or uneven or dangerous pathways, to create safe pathways for pedestrians.

- Crane access: Due to their considerable weight, cranes might not have a safe or stable footing on certain construction sites. Steel Road Plates can be used to reinforce the ground and provide a stable base for cranes and other heavy construction equipment.

- Concrete protection: Steel Road Plates can be placed directly on concrete surfaces to protect them from potential damage caused by heavy loads, equipment, foot traffic, and other impacts.

- End plates for shoring boxes: Steel Road Plates can be installed in excavations or trenches as end plates to provide support at the end of the trench when using traditional shoring boxes. Steel Road Plates are often used for end shoring when a shoring panel is too large, and so a smaller solution, such as a 1200mm road plate, can be used instead. All of Shore Hire’s Steel Road Plates also come with 4 corner lifting points, meaning they can be lifted vertically and easily placed into an excavation if required.

WHAT ARE SOME OF THE FEATURES OF SHORE HIRE’S STEEL ROAD PLATES?

One of the main features of our Steel Road Plates is that they come with a Steel Plate Lifter, which promotes efficient and safe installation and removal, giving customers complete control and stability when lifting and placing our range of Steel Road Plates.

Using the Steel Plate Lifter eliminates the need for manual handling or the use of a crowbar, reducing the risk of a workplace injury and ensuring adherence to workplace health and safety standards.

The vast majority of our Steel Road Plates have an anti-slip coating to make them fully non-slip. This enhances their grip and function, reducing the chance of vehicles or pedestrians slipping, especially in wet weather. This anti-slip coating is added to our Steel Road Plates by a process called sandblasting. Sandblasting is a method where small bits of abrasive material are propelled at high speeds against our road plates, in this case, to roughen their smooth surface, which helps in applying the anti-slip coating effectively.

50mm thick Steel Road Plates often have a thick edge that can damage vehicles, including bikes, wheelchairs, and mobility scooters. So, Shore Hire has developed a chamfered edge to reduce plate edge impact and ensure the plates are as safe as possible for vehicles.

WHAT ARE SOME OF THE BENEFITS OF STEEL ROAD pLATES?

Shore Hire’s Steel Road Plates offer a number of benefits to construction projects, including:

- DURABILITY: One of the biggest benefits of Steel Road Plates for construction projects is their incredible durability. Made from high-quality steel, our plates are purpose-built to withstand heavy loads, harsh conditions, and corrosion.

- COST-EFFECTIVE: Steel Road Plates are one of the most cost-effective yet heavy-duty ways to cover excavations and provide temporary access to vehicles and pedestrians. They are far less expensive than alternatives such as concrete, culverts, or bridges, making them a great, budget-friendly solution.

- VERSATILITY: As discussed in a previous section, Steel Road Plates can be used in essentially any application that needs them, making them suitable for a huge variety of construction and infrastructure projects. They also come in a variety of sizes and thicknesses, and can also be cut or welded to fit any size or shape.

- ENVIRONMENTALLY-FRIENDLY: The primary reason our Steel Road Plates are environmentally-friendly is because they’re a hireable product. This means our entire range of road plates are constantly being reused across multiple projects. Steel Road Plates are also incredibly durable, meaning that while they are in use on a project, they’re not going to get damaged, and can therefore be used again and again on other products.

- SHORE HIRE’S EXPERTISE AND SUPPORT: When you hire a Shore Hire Steel Road Plate, you’ll receive outstanding service and support. We have a revolutionary new tool that allows you to view our Steel Road Plates in real-time and true-to-size on your job site thanks to augmented reality. We also have a range of complimentary lifting accessories, such as lifting chains and our Steel Plate Lifter, that are tested and tagged to Australian Standards, so you know that every safety checkbox is ticked when you use our products.

HOW ARE STEEL roAD PLATES iNSTALLED?

Due to their weight, our Steel Road Plates cannot be moved manually and need to be lifted or repositioned using a machine, such as a crane, backhoe, or excavator.

They need to be securely fixed to the ground or surface the plate is going to be sitting on or over, to eliminate ground movement of the plates due to bouncing or moving. To account for variations in ground levels cold mix bitumen should also be utilised to ensure a smooth transition from plate to ground.

This is typically done by pinning the Steel Road Plate to the ground with fastening items, such as deck pins, or recessing (cutting out) the ground the Steel Road Plate will be sitting on so the plate can sit flush to the ground.

sHOULD YOU BUY OR HIRE STEEL ROAD PLATES?

Whether you buy or hire Steel Road Plates for a project depends on a number of factors, including the duration of the project, the intended use of the plates, the required size and load capacity of the Steel Road Plates, and budget constraints.

For example, if you only need to use a Steel Road Plate on your project for less than a few months, then hiring is a great option, but, if you think you’ll ned the plate for a year or more than buying the plate will usually be a more cost-effective option.

You would need to buy Steel Road Plates primarily because of the specific size required for a project. If you need an unusual size that is not readily available from Shore Hire, we can custom-manufacture steel plates to meet your exact specifications. However, in these cases, it’s likely that the plate will need to be purchased rather than hired, as hiring options for non-standard sizes is uncommon. The other common use case for Steel Road Plate purchase would be if the plate is going to be sacrificed or destroyed as part of its application.

If you would like to learn more about our Steel Road Plates, or any of our other traffic management products, visit your nearest branch, email [email protected], or call our friendly team of experts at 1300 SHORE HIRE.