Home Blog Product Info Shore Hire’s Guide to Jack and Lifting

Jacking and lifting play an essential role in construction and infrastructure projects, whether lifting heavy loads or stabilising structures.

At Shore Hire, Jack & Lifting is more than just the supply of tools and equipment. Our skilled engineers and riggers can work with you and your project engineers to develop a jacking, lifting, and structural support solution that can be installed by our rigging team.

In this blog post, you will learn everything you need to know about hydraulic jacking systems, what construction applications they can be used for, the different types of jacking and lifting equipment we have, and the services we can provide for these products.

What is Jacking and Lifting?

Jacking and lifting refers to the process of raising, lowering, stabilising, or supporting heavy loads using specialised equipment, such as hydraulic jacks.

Hydraulic jacks work based on the principles of hydraulic pressure, using fluid (typically oil) to create enough pressure in a cylinder to lift heavy loads.

What Can Hydraulic Jacks Be Used For?

Hydraulic jacks are versatile pieces of equipment that can be used for various purposes, but they are primarily used for controlled lifts, controlled descents, and load monitoring.

The applications for jacking and lifting are wide and varied in the construction industry, but some of the most common applications are:

- Bridge works and maintenance to raise or lift an entire section of a bridge or specific structural components of the bridge

- House jacking to raise a structure to allow works to be completed underneath, such as to build stilts to protect it from flooding, or to allow the structure to be more easily removed from site

- Bearing or component replacements in bridges and heavy machinery

- In the shipping industry for loading ramp weighing and boat stabilisation during docking works

- Building alignment, which is especially applicable if a structure has sagged or moved over time

- Staged lifting works for buildings and heavy equipment

- Load transfer and pre-stressing of slabs, buildings, and bridges

- Structural support for holding up beams or walls during construction projects

- Raising large machinery for installation or realignment

- Lifting and supporting heavy machinery such as mining vehicles and excavators for maintenance and repairs

What Types of Jacks/Lifting Equipment Does Shore Hire Offer?

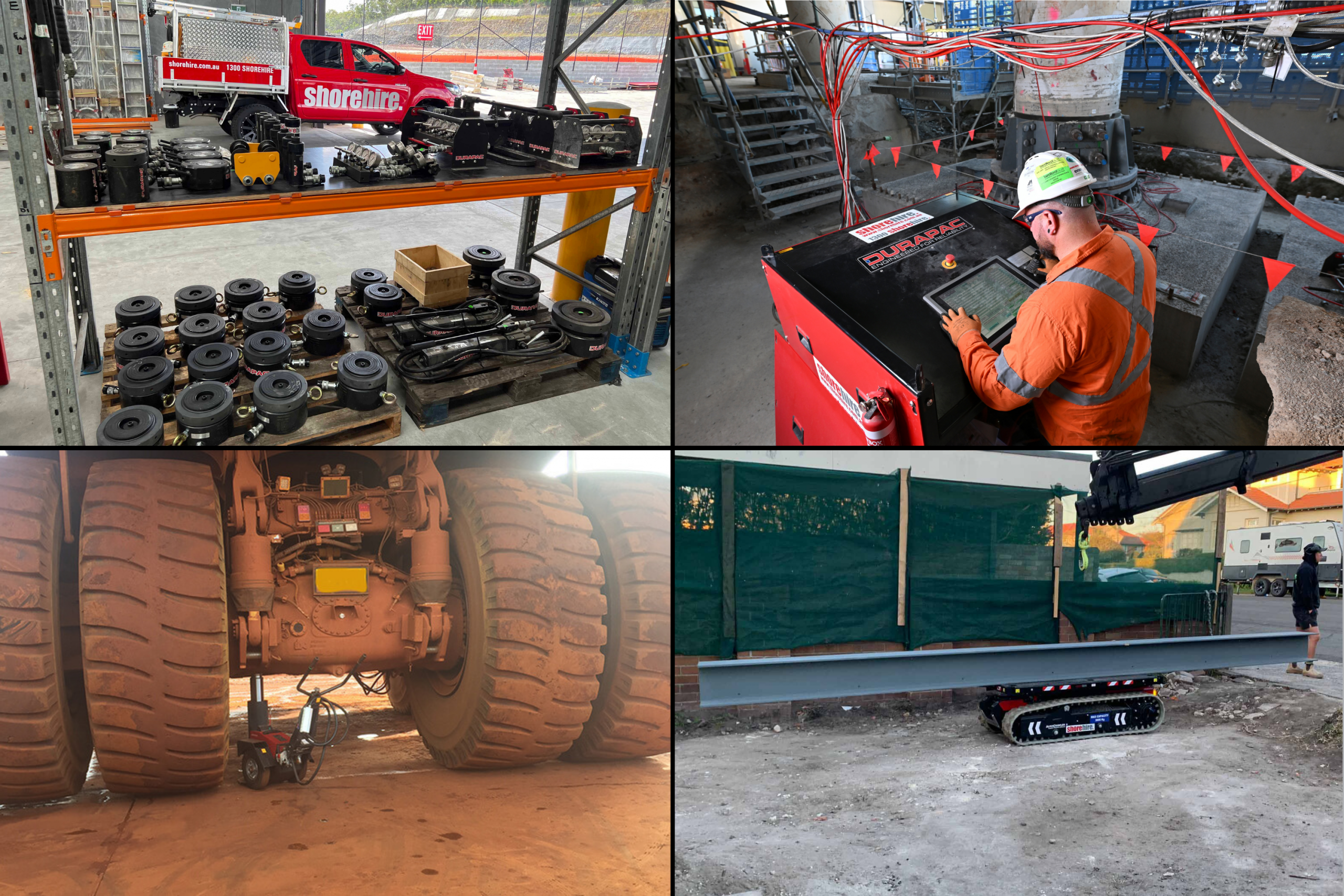

- Hydraulic Jacks: We have an extensive range of hydraulic jacks designed to support various project requirements, including flat jack cylinders, low height cylinders, general purpose cylinders, pancake lock nut cylinders, and high tonnage cylinders. We also have a range of accessories to complement our jacks, including electric pumps, manual hand pumps, hoses, gauges, and manifolds. Our hydraulic jack range is also often used in tandem with our temporary propping solutions.

- Synchronised Hydraulic Jack: Our synchronised hydraulic jacking system, the Sync Master, is an advanced hydraulic system designed for precision lifting and synchronisation. It is fully wi-fi enabled, and can concurrently monitor up to 32 individual lifting points. The system’s wi-fi enablement allows remote monitoring of shifting loads with phone alerts for any changes outside of tolerance so you can have full peace of mind that your project is moving along safely.

- Heavy Vehicle Power Jack 200: The Heavy Vehicle Power Jack 200 is a versatile lifting jack and heavy-duty vehicle jacking stand specifically designed for use with large mining vehicles. It features patented internal locking quadrants, which are immersed in oil and remain consistently engaged throughout the lifting process, ensuring a failsafe operation. Compact and easily portable, the Heavy Vehicle Power Jack 200 is the ideal choice for both workshops and service vehicles.

- Multi Loader 3.0FX: The Multi Loader 3.0FX is a flatbed-tracked carrier used to assist with transporting equipment on-site, especially on projects with tight or limited access. Although the carrier is lightweight and comes in an extremely compact size, it is incredibly powerful, having a rated capacity of 3000kg. It has telescopic beams on each corner to support extra large loads, and these can be positioned manually, extending the platform either longitudinally or laterally. The versatile system also features a swivel platform that can be positioned in 16 different places, so the platform can be angled to suit your specific load.

Shore Hire’s Jacking Service

We provide a complete turnkey solution for any projects requiring hydraulic jacking.

Our own in-house specialist engineers can offer a complete range of temporary works solutions, ranging from concept designs to fully certified solutions.

Shore Hire’s on-site hydraulic jacking team are nationally recognised as the experts in the hydraulic jacking space, and will deliver a safe and efficient installation service that is delivered on time, every time. We also provide technical backup and load monitoring, prioritising safety at all times.

Engaging a specialist like Shore Hire to install or project manage hydraulic jacking can offer a number of benefits, including expertise, efficiency, safety, quality, and tailored solutions, ensuring the success of your project in every aspect.

For more information about hydraulic jacking or any of our jacking or lifting equipment, visit your nearest branch, email [email protected], or call our friendly team of experts at 1300 746 734.