Needle Beams

NEEDLE AND GRILLAGE BEAM SPECIFICATIONS

| Type | Length | Height | Width | Unit Weight | Weight Per Metre |

|---|---|---|---|---|---|

| 150UB18 | 2m | 155mm | 75mm | 40kg | 18kg |

| 150UB18 | 3m | 155mm | 75mm | 60kg | 18kg |

| 200UB22 | 2m | 202mm | 133mm | 50kg | 22kg |

| 200UB22 | 3m | 202mm | 133mm | 75kg | 22kg |

| 150UC30 | 2m | 158mm | 153mm | 65kg | 30kg |

| 150UC30 | 3m | 158mm | 153mm | 100kg | 30kg |

| 150UC37 | 2m | 162mm | 154mm | 80kg | 37kg |

| 150UC37 | 3m | 162mm | 154mm | 120kg | 37kg |

| 200UC52 | 2m | 206mm | 204mm | 110kg | 52kg |

| 200UC52 | 3m | 206mm | 204mm | 165kg | 52kg |

| 310UC118 | 2m | 315mm | 307mm | 250kg | 118kg |

| 310UC118 | 3m | 315mm | 307mm | 370kg | 118kg |

| 310UC118 | 4m | 315mm | 307mm | 490kg | 118kg |

Needle Beams

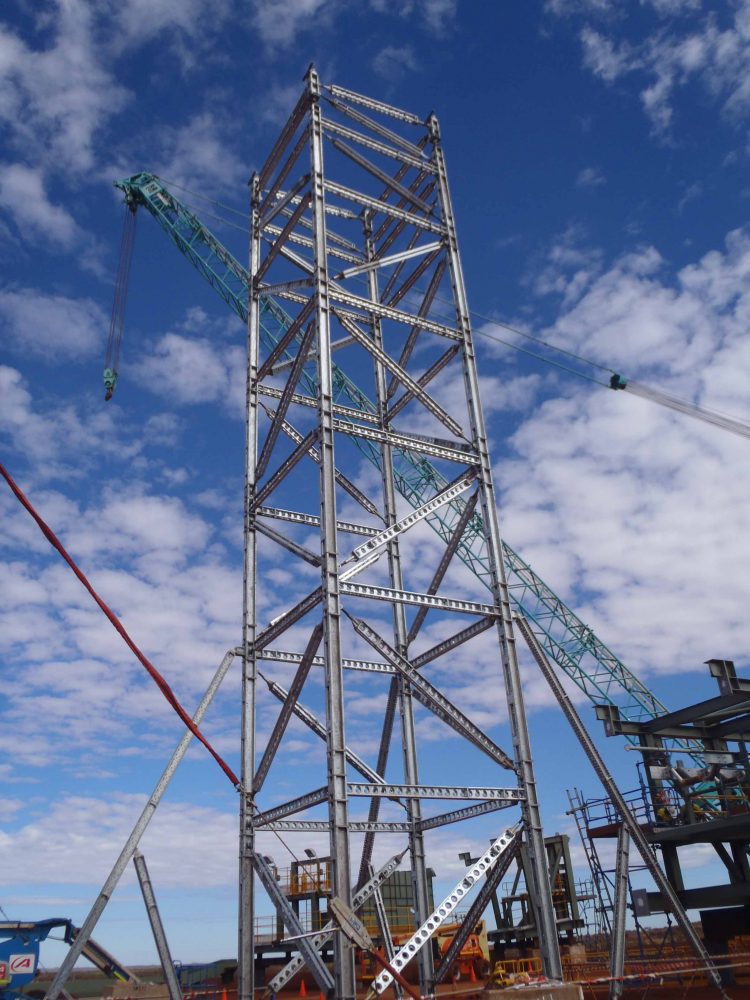

Shore Hire’s Needle Beams are designed for use in tandem with our bespoke propping systems for needling applications. The system works by spreading the load to either side of the penetration through the needle beam and then onto whatever temporary propping system is used on either side.

All of our needle beams have been reinforced with additional stiffener plates and galvanised for extra strength and protection.

Our needle beams are available in various sizes, which can be found in the adjacent table in both Universal Beam (UB) and Universal Column (UC) options.

As with all of Shore Hire’s propping products, the true value of this system Is not just in the product but also in the wealth of experience our engineering and rigging teams provide, Shore Hire can handle the engineering design and installation of any needling application you require to give you full peace of mind and confidence the job will be done efficiently and safely.

- Stiffener Plates added for extra strength

- Galvanised beams for added protection

- Designed to work perfectly with our other propping systems, such as our modular and titan props

- Can be installed for you by our on-site rigging team for full peace of mind and confidence

Shore Hire’s Needle Beams are designed for use in tandem with our bespoke propping systems for needling applications. A needling application is usually a penetration through a structure with a beam running through the structure onto a propping system on either side.

Download Tech Data Form

"*" indicates required fields

Download Form

"*" indicates required fields

Get a quick quote on "Needle Beams" now

"*" indicates required fields