Home Blog Product Info The Evolution of Shore Hire’s Counterweight Systems

At Shore Hire, we used to rely on traditional concrete counterweight systems as anchor points for our entire range of propping products, but we encountered problems with the accuracy of the weight and quality of the concrete blocks, as well as the constant need for drilling into the blocks.

Repeated drilling into different sections of the block (once a hole is drilled in one spot, that spot cannot be used again) caused the concrete to deteriorate over time, resulting in changes to the weight of the block and the overall capacity it could support.

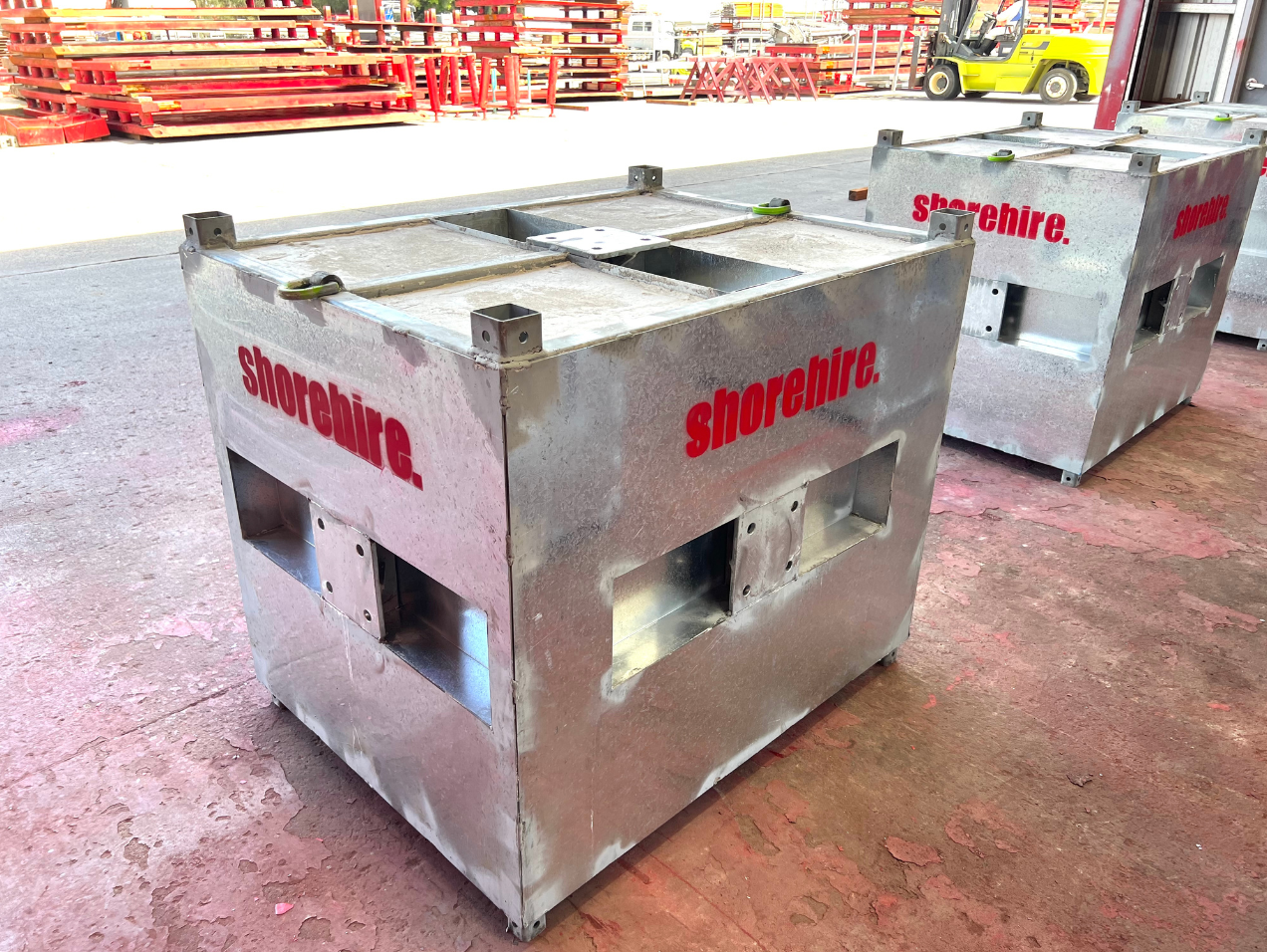

To address these challenges, Shore Hire developed our own counterweight system – our Engineered Blocks.

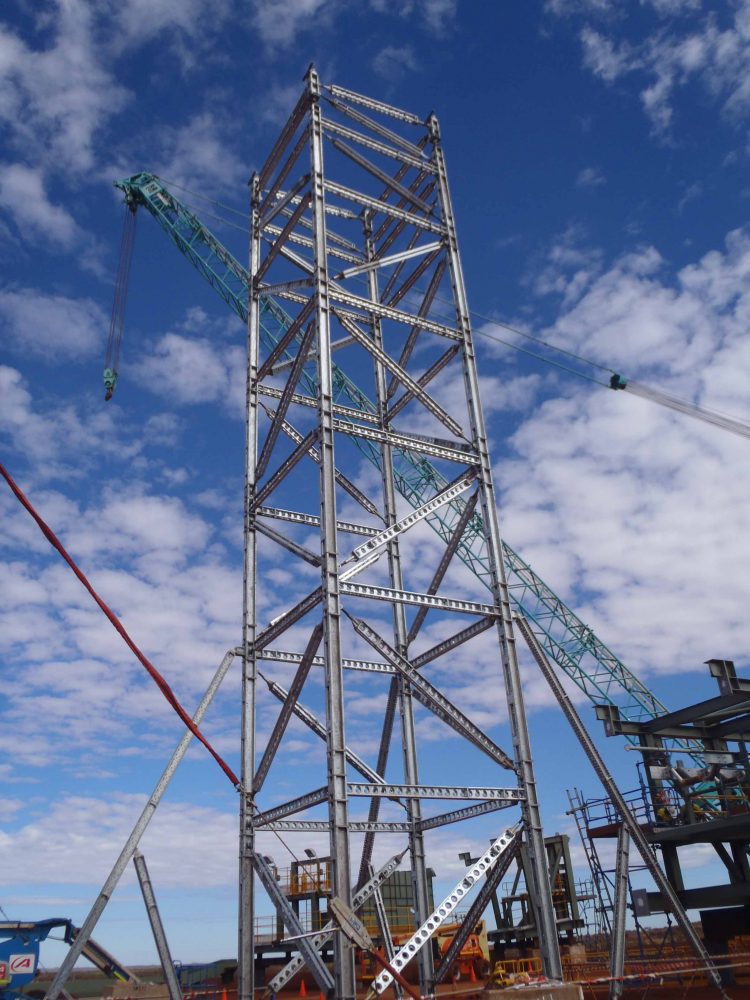

This system is Australia-made with galvanised steel, creating a robust, weather-resistant counterweight anchor block that can be used as a pole propping support, facade retention support, to tie down roofs subject to uplift, and as a temporary pad footing substitution.

Each face of our Engineered Blocks has a Modular Prop connector plate at its centre, and the ability to bolt into these connector plates eliminates the need for constant pre-and re-drilling of holes. This allows the system to maintain its integrity and mass for far longer than a traditional concrete counterweight.

Since launching our Engineered Blocks 18 months ago, they have quickly become a customer favourite.

At Shore Hire, we are committed to enhancing safety and efficiency on Australian job sites by continuously developing new proprietary items as our Engineered Blocks,

If you would like to how Engineered Blocks have been used on recent projects, head to our case study library.