Problema

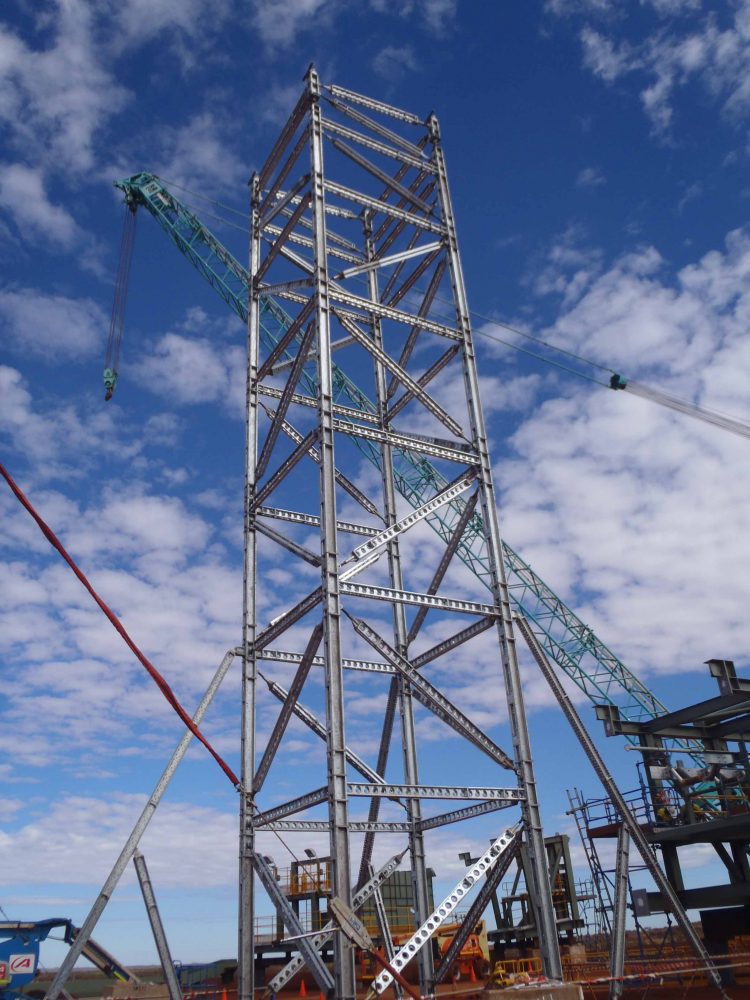

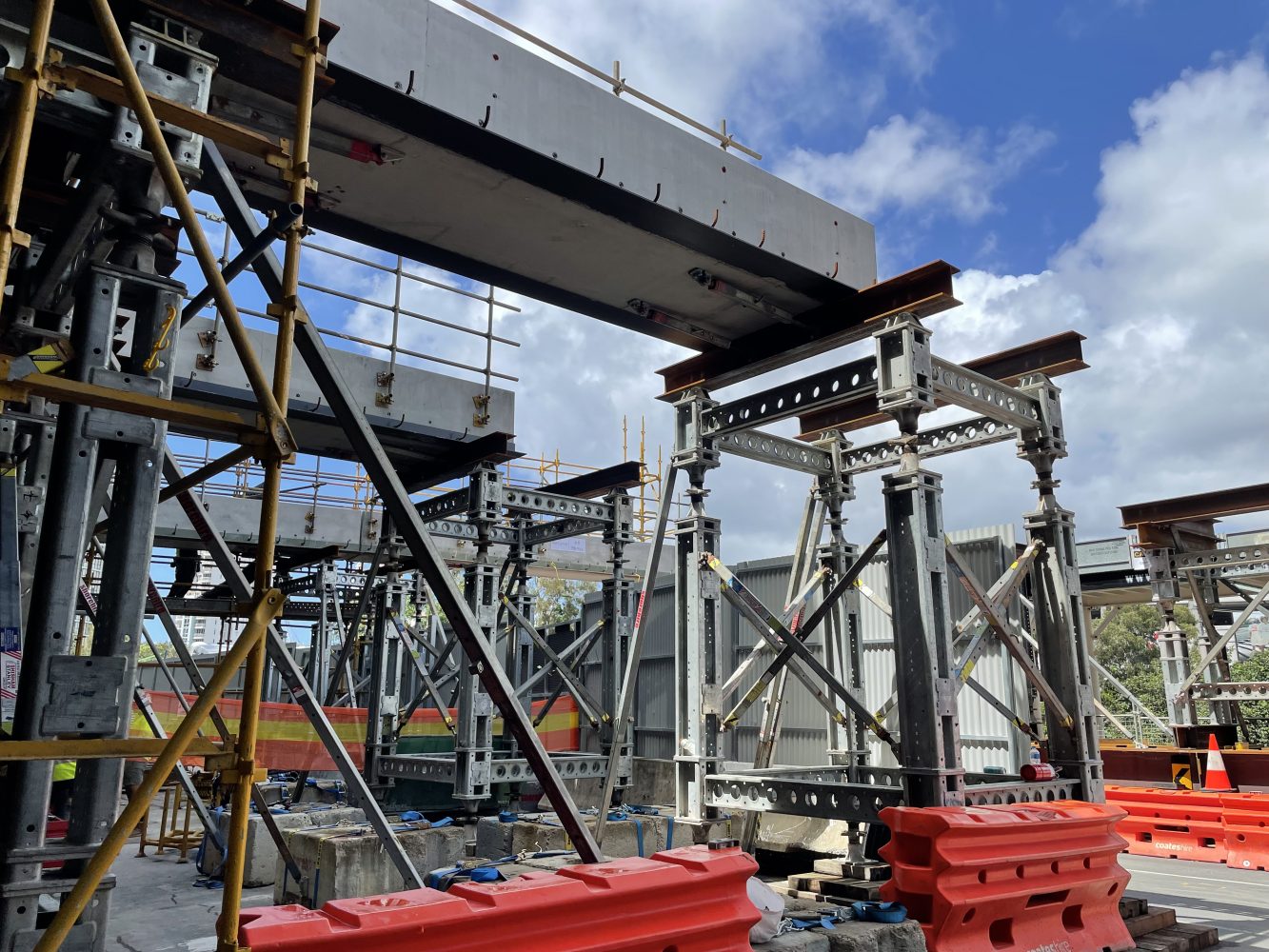

Shore Hire was contacted by a tier 1 client that had a major project requiring the support of precast shell beams. As the beams ran across a live service road and into an existing structure, the client needed a design to allow the support towers to have as small a footprint as possible. The loads on the towers were up to 140 tonnes so Shore Hire’s experienced team of engineers designed support towers out of our Modular propping systems (Shore 100, 400 and 1000) as well as a combination of tilt props and other cross-bracing that could support the loads but also work to the ground bearing capacity.

Solución

To save the client as much time and money as possible, Shore Hire prebuilt 90% of these propping towers before delivery to site, which saved an incredible amount of labour costs for the client. The prebuilding of these towers also enabled the client to minimise their footprint next to a major active commercial building and keep their client happy. Shore Hire also offered additional value with our engineering team liaising with all the required third-party engineers to ensure our design was capable of supporting the structures being installed.

Regular site checks and stock takes were run by Shore Hire’s Queensland propping manager and this resulted in clear and transparent communication throughout the entire project. There were also multiple instances in which existing designs needed to be changed on the run and Shore Hire’s dedicated team worked tirelessly to get these done in a timely fashion and meet the needs of our client while taking away the cost and pain of having to wait days for a redesign.