Problema

A client in Queensland needed an emergency propping job done as they had a vertical column in their factory which was hit with a forklift and so the above roof structure, which supported multiple overhead cranes, was compromised. To add further complications, every hour in which this warehouse could not operate the client suffered huge financial implications so a speedy and safe job was required to take their pain away.

Solución

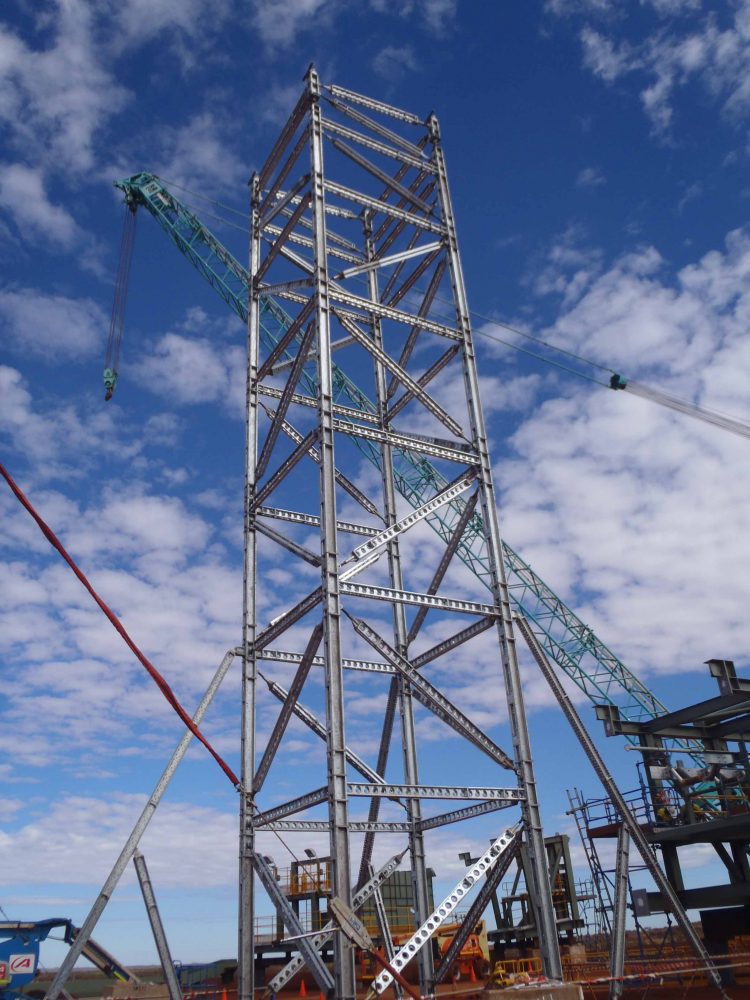

In order to meet the client’s needs Shore Hire’s engineering and rigging teams created a two-stage approach. Stage one is a make-safe to avoid any structural failings and stage two is a full propping solution so that rectification works could take place and the warehouse downtime could be minimal. Shore Hire designed, supplied and installed all equipment for this propping job.

Stage one was a make-safe with 2 Shore 1,000 props installed to get the overhead cranes back and operational for the client. Stage two was to then remove the make-safe props and install new Shore 1,000 props to support the roof beams. We also used Tilt Props to enable cross-bracing for added support to the Shore 1,000 props. A number of Hydraulic Jacks were also installed in order to lift the roof beams so that the damaged vertical column could be swapped out with a new column.

This project saw significant time constraints due to the factory not wanting to be closed for too long. Shore Hire was able to work into the client’s tight weekend shutdown window and get everything dismantled on Sunday before the client reopened for business on Monday. Shore Hire also worked in and around multiple trades; such as the crane company, fabrication company, electrical contractors and more.