المشكلة

Shore Hire were called upon by a structural engineering firm to design a propping solution to support a 500 tonne crane and having already explored a few methods themselves the firm engaged Shore Hire as they knew they needed to come up with an innovative solution.

The problem here was that the crane needed repairs to its support legs, but it was too heavy to simply lift off the ground. Shore Hire needed to find a way to temporarily prop and hold up the entire weight of the crane while the repairs were being carried out.

SOLUTION

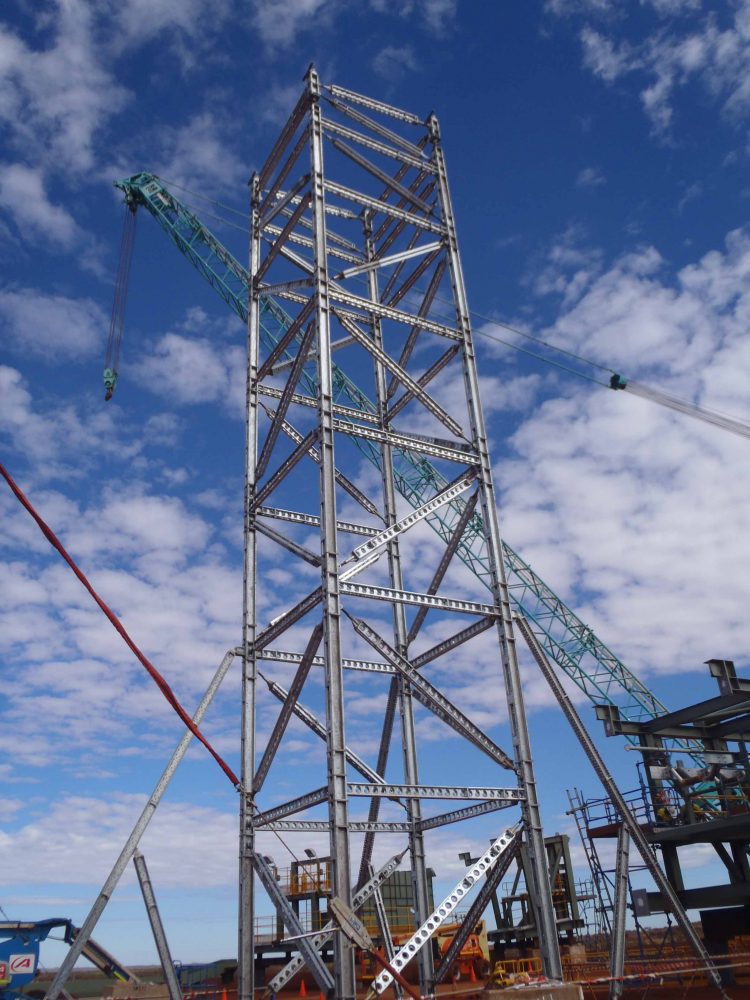

To solve this problem, Shore Hire recommended the Shore 400 system. This modular and versatile system was ideal for the scenario because it could be easily customized to fit the specific needs of the project without the cost, difficulty, and time frame associated with a fabricated and fixed structure.

Using the Shore 400 system, Shore Hire’s rigging and erection team were able to build a frame to hold up the entire weight of the crane. They were able to assemble the structure quickly and efficiently with the help of a mobile crane and boom lift.

The result was a win for the client, as they were able to get the crane operational again more quickly and far more cost-effectively than would have been possible with a different solution. The Shore 400 system’s versatility and ease of assembly played a critical role in the success of the project. Overall, this project demonstrates the value of innovative thinking and the importance of finding the right solution for even the most challenging problems.