Shore Brace 400 Hydraulic Bracing System

Shore brace 400 specifications

| Description | Length(mm) | Section (mm) | Weight (kg) |

|---|---|---|---|

| 500mm Extension | 500 | 356 x 368 | 420 |

| 1000mm Extension | 1000 | 356 x 368 | 600 |

| 2000mm Extension | 2000 | 356 x 368 | 835 |

| 4000mm Extension | 4000 | 356 x 368 | 1275 |

| 6000mm Extension | 6000 | 356 x 368 | 1705 |

| 6000mm Extension | 6000 | 356 x 368 | 1705 |

| 8000mm Extension | 8000 | 356 x 368 | 2135 |

| Shore Brace Ram Unit | 2150-3150 | 400 x 400 | 1415 |

Shore Brace 400 Hydraulic Bracing System

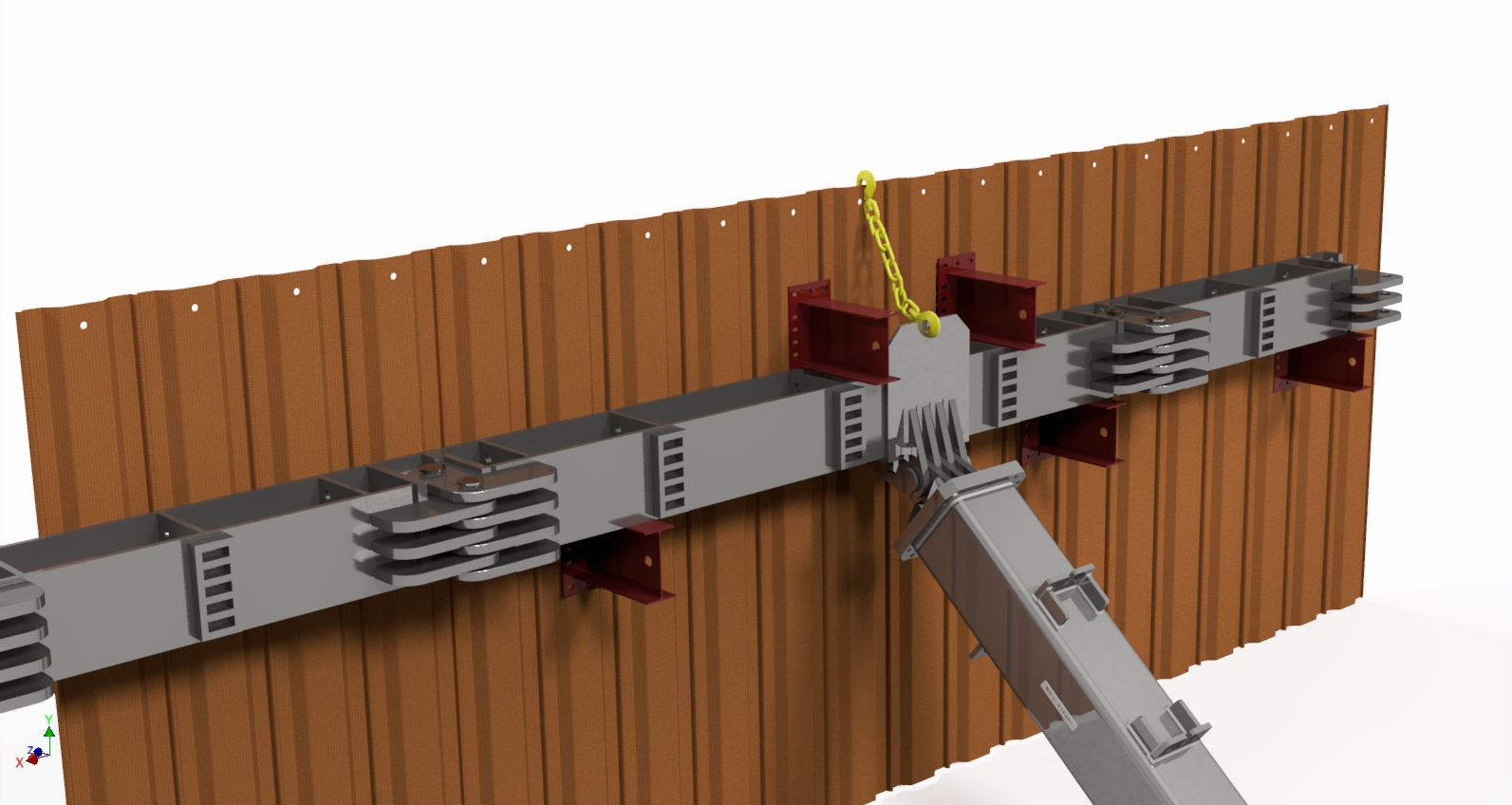

The Shore Brace 400 is a modular Hydraulic Bracing system comprising of various sized extension beams that are double-pinned and connected to a high-load capacity Hydraulic Ram. The system can be designed to support rectangle, square or multi-sided excavations up to 20m without cross supports, dependent on the engineering design and it is the bigger version of our Shore Brace 200 system.

With engineering review the addition of the high load Shore Brace 400 Hydraulic Cross Brace or corner brace, much larger and more complex perimeter support projects can be safely secured using our range of trench sheet, sheet piles or concrete capping beams.

Shore Hire have also recently developed the Shore Strut 400, which is a 1250kN Hydraulic Strut designed to be used in conjunction with the Shore Brace 400 system to eliminate the need for multiple cross struts in larger excavations.

Deep projects and sites can be safely shored using additional frames to increase the capacity of the system. The Shore Brace 400 Hydraulic System is designed by our in-house engineering team and Australian made so you have peace of mind that the equipment supporting your project is the safest and best gear available.

We also offer pre-assembly where possible and a technical on-site team who will walk you through the install process and provide build drawings so you know the exact step-by-step process required to ensure a quick and painless job well done.

- Designed by the expert Shore Hire Engineering team and manufactured by us here in Australia so you can be sure that you’re getting the best equipment possible

- Load monitoring system available for maximum safety and peace of mind

- Composite legs featuring simple corner pin for quick and easy install

- Double-acting hydraulics can be pumped both in and out for an improved operation, simplicity and less gear on site

- Various sizes can be combined to meet a range of excavation applications

- Cross brace, corner brace, and raking systems are available to suit any application

- Double pinned joint for maximum load capacity and strength

- Hydraulic lock-off valves so you have maximum control and safety

- Motorised hydraulic pump for easy adjustment of ram

- Pre-building of gear where possible to save you time and money on your site

- Technical product experts at your service to step you through the process on site

- Build drawings available to give you an easy-to-follow setup process

- Manufactured & Certified AS 4744.1-2000 so you know that every safety checkbox is ticked when you use our products

Owing to their flexibility, hydraulic bracing systems can be used for a huge variety of trench shoring applications including large tank installations, interceptor chambers, pump stations, stormwater pits, gross pollutant traps, bore pits, lift wells and more.

Shore Hire’s Shore Brace 400 Hydraulic Bracing System is designed to be used with steel trench sheets, sheet piles and potential modular cross braces if required to brace various-sized trenches, all of which are products we offer and can assist you with.

Should you require advice, we always recommend you speak to our technical sales team before any hire.

Download Tech Data Form

"*" indicates required fields

Download Form

"*" indicates required fields

Get a quick quote on "Shore Brace 400 Hydraulic Bracing System" now

"*" indicates required fields